7 years have passed since the first Blade (V120) was released in 2004. This, the latest product in the Blade series which continues to see growing users (mainly in the top swimmers including Olympic contestants) has finally been completed.

This model was named "Blade Zero".

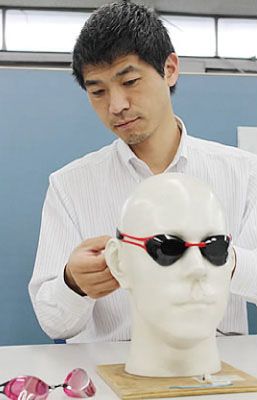

Development team told us some anecdotes from the Blade ZERO development process.

"Actually, we already had the image of the shape of ZERO back when we developed the original Blade (V120)" the development staff said. "However, it was not possible to create it because of technical problems, so we progressed with what was possible at the time, the Blade (V120), and Blade + 30. We gained a large following of competitive swimmers. So we were determined that our next model would embody the ideal shape of Blade that we had imagined for many years. This is the only way to reduce resistance.”

There was a strong commitment to past achievements and the low resistance achieved in the past seven years. Along the way there were many issues that arose for the developers. "Ideas for achieving low resistance with the Blade + 30 model were almost all tested, and the only thing left would be to eliminate the holes in the strap on the lens for improved low resistance."

They had had the idea of improving the side arm since developing the first Blade (V120), by replacing it with a strap that could be folded back directly, and inserted into the lens. This idea proved to be far easier said than done.

"To mould the side arm integrally with the lens, a very advanced moulding technique is required. And it will not work well if the balance of the pressure applied when moulding, the moulding temperature, etc. is off even just slightly. And also the mould must be 100% precise. Having different moulds for different colours was another trying factor.”

After the trial production, they came up with a prototype, and tested repeatedly,even beyond their desired date to conclude this product. Testing continued until they attained a result that they were satisfied with. Tabata proudly offers top level swimming goggle manufacturing technology in Japan, but even for them the task of achieving both an attractive finish combined with strength was extremely difficult.

When the first prototype was completed, there was a lot of criticism of its shape, even within the company. "A lot of good things and bad things were said. I think that is a sign of just how much everyone cared about the Blade series. And it was a source of motivation to work harder and improve on the prototype.”

They overcame many difficulties along the way, and finally when the new Blade was completed, The development team named the product “ZERO”, to signal to the origin of Blade.

The side arm, which is the biggest stand-out feature of Blade ZERO, is separated into two strips to offer better support, fixing the goggle lenses in place over a wider space, at the top and bottom. This one adjustment allowed us to fix shaking that occurs when diving or turning in the water that you experience with conventional goggles.

In addition, the side arm has a structure that is easier match the face shape. “The reduced water resistance and elimination of shake make these goggles feel like they are part of your face. I want all competitive swimmers to try them out.”

The team achieved even further resistance reduction by adopting this side arm. By integrally moulding it with the lens, the hole of the strap was no longer needed, and the projecting surface area was cut by 5% compared to the conventional Blade (V120).

"I think it doesn't really look like much if you focus on just the number of 5%, but as the Blade series itself is already highly developed to reduce water resistance, this is pushing it even further. Ishikawa, who belonged to the swimming team himself during his student days commented that, “We asked a real university swimming team to be our monitors, and almost all agreed that there was less resistance compared to past Blade models”.

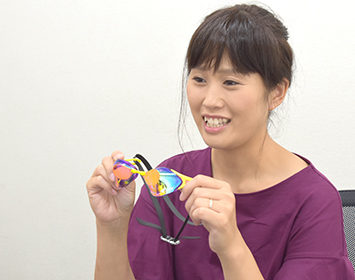

"Blade ZERO has also focused on colouring and has adopted new colours such as DMV (Dark Mauve) and GBL (Grand Bleu) for our racing model. In particular, the dark mauve looks great on both men and women, and creates a strong look. It is my personal favourite.” Ishikawa has a DMV Blade ZERO and goes to the pool every week.

“Friends that I go with often comment that they look great and that they like them.” And as someone who was involved in the development it brings me great joy to hear such things.

Abe once said that, "Since the London Olympic Games will be held in 2012, I would love for the Blade ZERO to help the Japanese swimming team get medals”. So he cheered on the competitors in the run up to the games on every day off he got.

"Recently, the number of competitive swimmers using the Blade series is increasing greatly. And when I see them working so hard and doing their best, I feel driven to create even better products.” Abe shared while narrowing his eyes.

"But since Blade ZERO is really at its ideal form, it is complete. It would be a huge task to improve on it. But that reason alone is why I believe this is something that can only be achieved here at Tabata."