Last year, loss of face pads amounted to almost half (47.8%) of all goggle part loss related enquires to the Tabata customer service line. While silicone face pads are excellent in durability and fitting, on the other hand, there was a problem of easily becoming dislodged compared to other materials.

The development staff started his research to solve this problem.

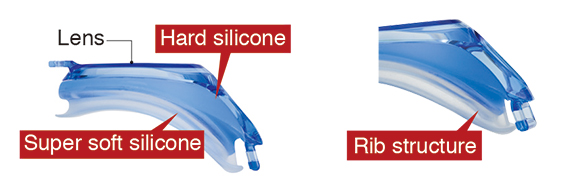

The softer the fitting material the better it fits, but if it is too soft it will detach from the lens easily. If it is very hard it wouldn’t detach from the lens, but would be useless as a fitting material. In order to solve this problem, the team used two materials with varying levels of hardness. One was a relatively hard material, and was to be used on the part covering the lens, and the other was a soft material for the part directly touching the face.

There was also a way to combine the soft material and a hard material using adhesive, but considering that it would be used close to the eyes, even if it had minimal effect, we decided that using adhesive would not be a viable option. Even if the team were to use the adhesive, the process would be very inefficient, thus resulting in a significant cost increase. So the next issue arose; what would be the best way to combine both materials? What shape is easy to stick to and easy to mold? Abe had been looking at the products that he had worked on the development of in the past. And that is when he came up with the idea that the technology of manufacturing silicone materials of two different hardness for foot care products could be applied here too.

After trial and error, the development staff learned to make swimming goggles with two kinds of silicone materials of varying hardness. He concluded that that manufacturing method was the best at the present time. The development staff believed that by using this technology, they would be able to make goggles that match more people's faces. And so his new challenge began.

Combining soft and hard silicones; It is easy to simply mix these materials, but is is paramount to separate them at a fixed position. The team went from it being impossible, still impossible, and then to possible but with high costs. The average time period for product development is one year, but these Double Fit goggles took a period of two years. Challenges faced were finding a moulding method commensurate with cost, and also considering cost demands from sales. The cost could not exceed current models.

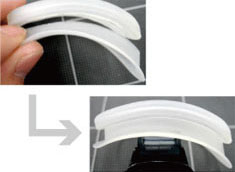

The trial production No. 1 was concluded to have too strong suction and eye area was being pushed out. It certainly fit many face shapes, but it was far from optimal. If you use a soft material with no strength in the part directly in contact with the face, it fits more face shapes. However, if it is too soft, the hardness of the lens will be felt through the pad, causing discomfort. And on top of that, the pressure is too strong, the swimmer would be left feeling like their eyes were bulging. How did the team deal with this unnecessary suction? If they simply worked with harder material the optimal fit would be lost.

The development staff who was at a loss, and decided to head home one cold evening. He continued to think about the goggles while eating udon that his wife had made for him. He thought about how mochi rice cakes are soft, but Sanuki Udon has a strength that makes them an appetite pleaser. "Sanuki udon is soft and stretchy like mochi rice cakes, but is strong” "What happens if the face pad also had a similar strength?"

He got an idea for adding strength to the face pad.

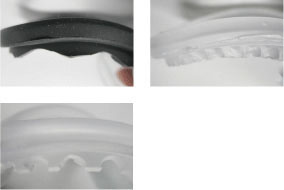

The development staff paid attention to the fact that when the strap is overstretched the shape of the outside corner of the face pad was the section that the shape changed most. He realised that they didn't need to change the shape of the part of the outer corner of the eye. He decided to strengthen this section to eliminate the feeling of pressure when wearing.

His idea was right.

He was successful in eliminating unnecessary deformation by strengthening the corner of the face pad (rib structure).

This reduces pressure when wearing, and making them more enjoyable and comfortable when swimming, even for a long period of time, without feeling like they have stuck to users face. Not only had they come up with a great fitting goggle, they had also created a never seen before fit that isn't overly clingy. I highly recommend everyone to try out this new fit.